Effort Foundry’s growth into the Military/Navy/Nuclear casting market continues to grow, accounting for over 40% of total output.

The growth over the last 12 months was sparked by the addition of Cu-Ni alloys as a Level 1 supplier. Additionally, both Electric Boat and Newport News have added Effort to the approved casting vendor list. Nuclear castings orders continue to increase as the need for castings in the growing market continues. Effort is working with European Nuclear casting buyers to serve this growing market.

Newport News Shipbuilding (NNS) strives for the highest quality in the manufacturing of their products. This includes having their suppliers provide the highest quality compliant material and services.

Newport News Shipbuilding has for more than 135 years built ships that have served the nation in peace and war, in times of adversity and in times of abundance. The legacy of “Always Good Ships” includes the design, construction, overhaul, and repair of more than 800 ships for the U.S. Navy and commercial customers.

Effort Foundry has successfully passed the Electric Boat Foundry Assessment and Audit. The assessment/Audit was completed on November 9, 2023. The successful Assessment/Audit places Effort Foundry on the Electric Boat “Approved Foundry Vendor” list, which allows Effort Foundry, Inc., to produce castings directly for Electric Boat in all metals, including 70/30 (copper-nickel).

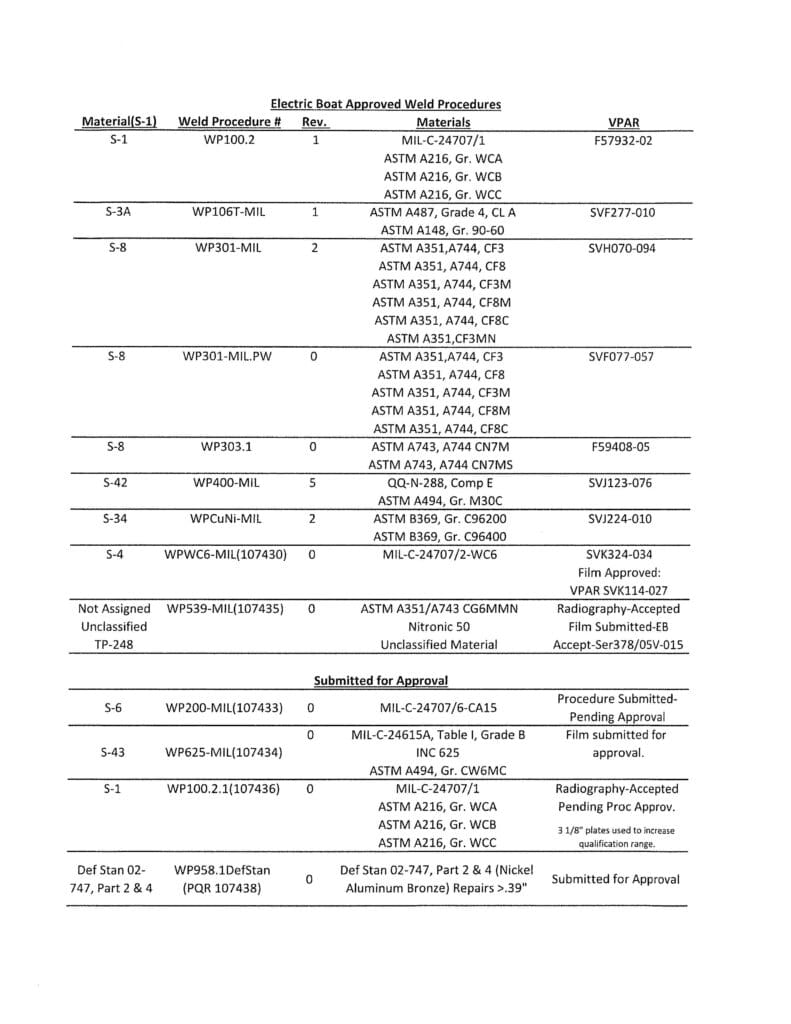

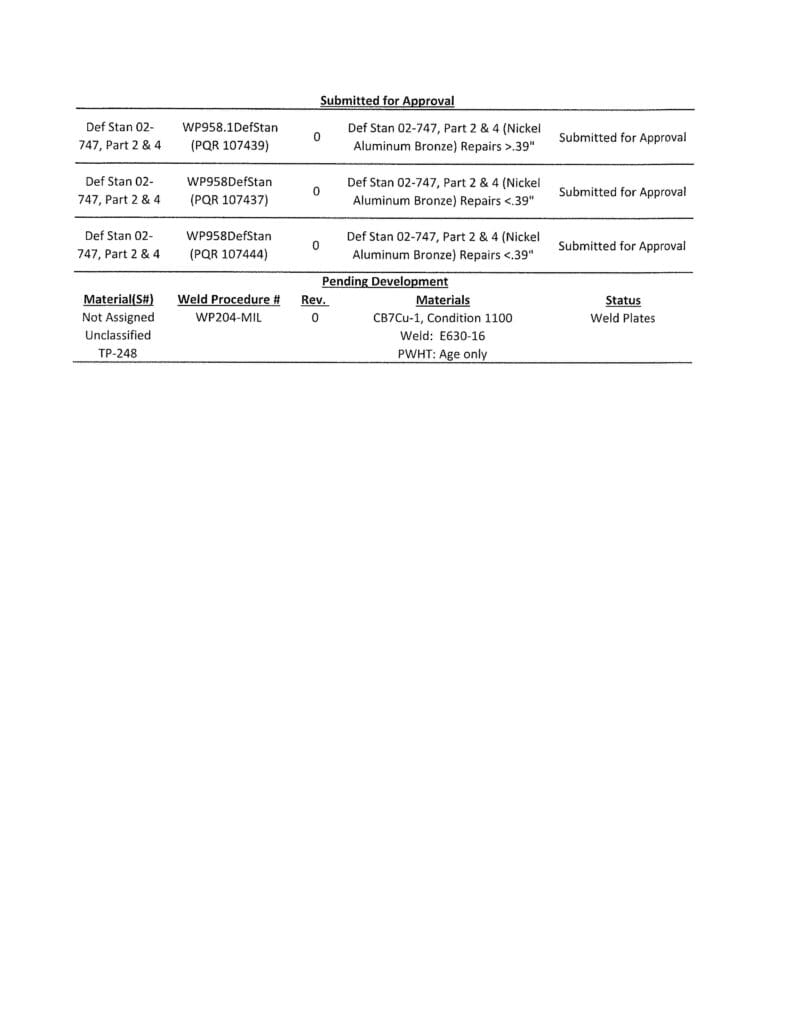

Effort Foundry is in Year 2 of enhanced cybersecurity to meet the increasing requirements of Military/Navy. Included below is a list of weld procedures approved by Navy for upgrading castings. Effort Foundry will work with customers to add to this list AS NEEDED.

Our 60,000 ft2 facility, located in Bath, Pennsylvania, houses each and every operation required in the casting process. It’s all here—from engineering and patternmaking to production, quality, and shipping.

Over the last decade, we have added 14,000 ft2 of dedicated machining and non-destructive testing space, a new sand reclamation plant, new grinding- and burn / arc facilities, and new blasting equipment.

To our customers, this means more of the same Effort quality you’ve come to expect, with even faster turnaround.

List of Weld Procedures