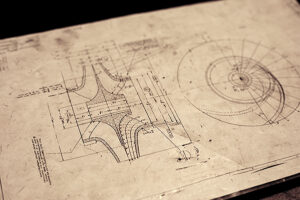

It Takes Effort to Make Quality Castings

Effort Foundry prides itself in craftsmanship, client responsiveness, and attention to detail.

Service

Customers receive weekly updates and milestone charts for all projects. We work to work specifications and communicate throughout the entire process.

Quality

In-house capabilities of Level III MT, LP, Level II UT, Positive Material Identification, Modeling / Simulation, Rough and Final Machining, Video Scope Inspection, Radiography, Testing: Charpy, Hardness, and Tensile Properties, Spectrographic Lab, over 150 ASME IX / Military-Approved weld procedures.

Delivery

On-time delivery on 88% of all orders. We understand that meeting deadlines is important to your business — so it is also important to ours!

Get in Touch

Please reach out to us:

Foundry office

6980 Chrisphalt Drive

P.O. Box 158, Bath, PA 18014

Give us a ring

Phone: 610-837-1837

Hours: Mon–Fri, 7:00 a.m.-4:00 p.m.