Effort Foundry, Inc. in Bath, PA, casts over 50 different alloys from grey iron, ductile iron, ni-resist, carbon and low alloy steels, manganese steel, martensitic/austenitic stainless steel, nickel alloys, and copper-nickel alloys.

The foundry uses a phenolic urethane binder system (no-bake) to produce sand molds and cores using traditional patterns and core boxes.

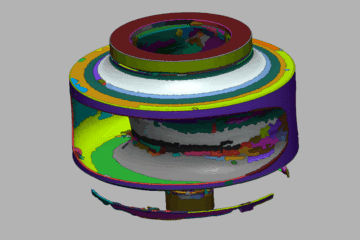

In addition, Effort Foundry, Inc., is a leader in patternless casting production. The process requires a model of the needed casting supplied by our customer or produced by Effort Foundry. The model is converted to a sand print model by Effort Foundry engineers to directly print the mold and cores for the foundry to cast molten metal in. This produces a high-quality casting meeting our customer specifications with no pattern required. The lead time of printed molds and cores is usually less than the lead times of creating a new pattern and is more cost-effective if this will be a one-time casting purchase.

Another option for producing castings with no traditional pattern and core box also starts with a model of the required casting that foundry engineers convert to a tool path for a 5-axis machine center to produce a one-time Styrofoam™ pattern, at a substantially lower cost and lead time than a traditional wooden pattern.

If you are interested in a casting purchase using a patternless system, please contact Danielle Johnson, Sales Manager, Effort Foundry, 610-837-1837 or djohnson@effortfoundry.com.